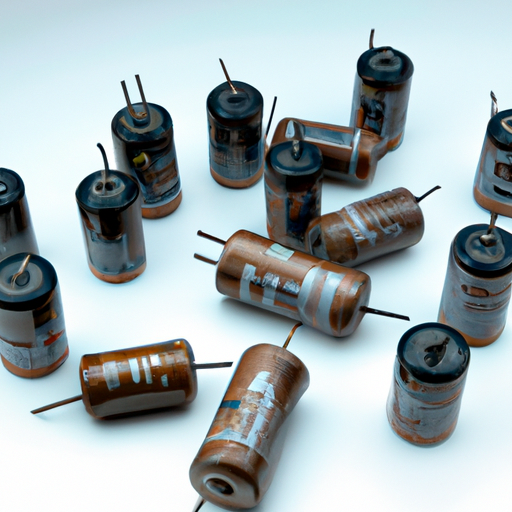

Oxidation capacitors are a type of capacitor that uses an oxide layer as the dielectric material. This oxide layer is created through a process called anodization, where a metal electrode is oxidized to form a thin layer of oxide on its surface. This oxide layer acts as the dielectric material in the capacitor, allowing it to store and release electrical energy.

1. Aluminum Oxide Capacitors:

Aluminum oxide capacitors are one of the most common types of oxidation capacitors. They are made by anodizing an aluminum electrode to create a thin layer of aluminum oxide as the dielectric material. Aluminum oxide capacitors are known for their high capacitance values and low leakage currents, making them ideal for applications where high capacitance and low leakage are required.

These capacitors are commonly used in power supplies, audio equipment, and other electronic devices where high capacitance values are needed. They are available in both through-hole and surface mount configurations, making them versatile and easy to integrate into various circuit designs.

2. Tantalum Oxide Capacitors:

Tantalum oxide capacitors are another popular type of oxidation capacitor. They are made by anodizing a tantalum electrode to create a thin layer of tantalum oxide as the dielectric material. Tantalum oxide capacitors are known for their high reliability, stability, and low equivalent series resistance (ESR), making them ideal for applications where high performance and long-term reliability are required.

These capacitors are commonly used in telecommunications equipment, medical devices, and other high-reliability applications. They are available in both solid electrolyte and wet electrolyte configurations, offering designers flexibility in choosing the right capacitor for their specific application requirements.

3. Niobium Oxide Capacitors:

Niobium oxide capacitors are a newer type of oxidation capacitor that is gaining popularity in the electronics industry. They are made by anodizing a niobium electrode to create a thin layer of niobium oxide as the dielectric material. Niobium oxide capacitors offer high capacitance values, low leakage currents, and excellent stability over a wide temperature range, making them ideal for high-performance applications.

These capacitors are commonly used in aerospace, automotive, and industrial applications where high reliability and performance are critical. They are available in both solid electrolyte and wet electrolyte configurations, offering designers a wide range of options to meet their specific application requirements.

4. Hybrid Oxide Capacitors:

Hybrid oxide capacitors are a combination of different oxide materials, such as aluminum oxide and tantalum oxide, to create capacitors with unique performance characteristics. These capacitors offer a balance of high capacitance values, low leakage currents, and excellent stability, making them ideal for a wide range of applications.

Hybrid oxide capacitors are commonly used in consumer electronics, automotive systems, and renewable energy applications where a combination of high performance and reliability is required. They are available in various configurations, including surface mount and radial lead, making them versatile and easy to integrate into different circuit designs.

In conclusion, oxidation capacitors are an essential component in modern electronic devices and applications. The mainstream models of oxidation capacitors, such as aluminum oxide, tantalum oxide, niobium oxide, and hybrid oxide capacitors, offer a wide range of performance characteristics to meet the diverse needs of designers and engineers. By understanding the features and applications of these capacitors, designers can choose the right model for their specific requirements and ensure the reliable operation of their electronic systems.

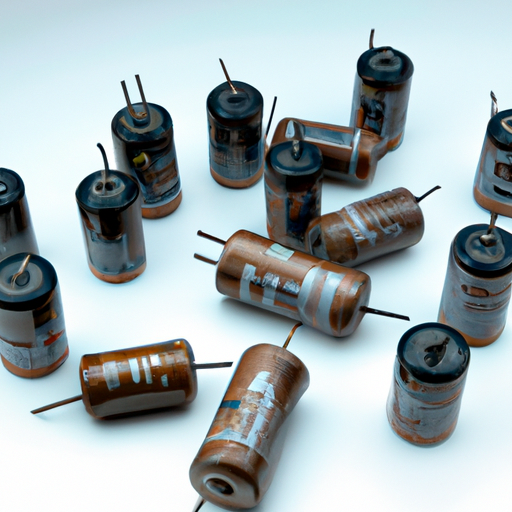

Oxidation capacitors are a type of capacitor that uses an oxide layer as the dielectric material. This oxide layer is created through a process called anodization, where a metal electrode is oxidized to form a thin layer of oxide on its surface. This oxide layer acts as the dielectric material in the capacitor, allowing it to store and release electrical energy.

1. Aluminum Oxide Capacitors:

Aluminum oxide capacitors are one of the most common types of oxidation capacitors. They are made by anodizing an aluminum electrode to create a thin layer of aluminum oxide as the dielectric material. Aluminum oxide capacitors are known for their high capacitance values and low leakage currents, making them ideal for applications where high capacitance and low leakage are required.

These capacitors are commonly used in power supplies, audio equipment, and other electronic devices where high capacitance values are needed. They are available in both through-hole and surface mount configurations, making them versatile and easy to integrate into various circuit designs.

2. Tantalum Oxide Capacitors:

Tantalum oxide capacitors are another popular type of oxidation capacitor. They are made by anodizing a tantalum electrode to create a thin layer of tantalum oxide as the dielectric material. Tantalum oxide capacitors are known for their high reliability, stability, and low equivalent series resistance (ESR), making them ideal for applications where high performance and long-term reliability are required.

These capacitors are commonly used in telecommunications equipment, medical devices, and other high-reliability applications. They are available in both solid electrolyte and wet electrolyte configurations, offering designers flexibility in choosing the right capacitor for their specific application requirements.

3. Niobium Oxide Capacitors:

Niobium oxide capacitors are a newer type of oxidation capacitor that is gaining popularity in the electronics industry. They are made by anodizing a niobium electrode to create a thin layer of niobium oxide as the dielectric material. Niobium oxide capacitors offer high capacitance values, low leakage currents, and excellent stability over a wide temperature range, making them ideal for high-performance applications.

These capacitors are commonly used in aerospace, automotive, and industrial applications where high reliability and performance are critical. They are available in both solid electrolyte and wet electrolyte configurations, offering designers a wide range of options to meet their specific application requirements.

4. Hybrid Oxide Capacitors:

Hybrid oxide capacitors are a combination of different oxide materials, such as aluminum oxide and tantalum oxide, to create capacitors with unique performance characteristics. These capacitors offer a balance of high capacitance values, low leakage currents, and excellent stability, making them ideal for a wide range of applications.

Hybrid oxide capacitors are commonly used in consumer electronics, automotive systems, and renewable energy applications where a combination of high performance and reliability is required. They are available in various configurations, including surface mount and radial lead, making them versatile and easy to integrate into different circuit designs.

In conclusion, oxidation capacitors are an essential component in modern electronic devices and applications. The mainstream models of oxidation capacitors, such as aluminum oxide, tantalum oxide, niobium oxide, and hybrid oxide capacitors, offer a wide range of performance characteristics to meet the diverse needs of designers and engineers. By understanding the features and applications of these capacitors, designers can choose the right model for their specific requirements and ensure the reliable operation of their electronic systems.