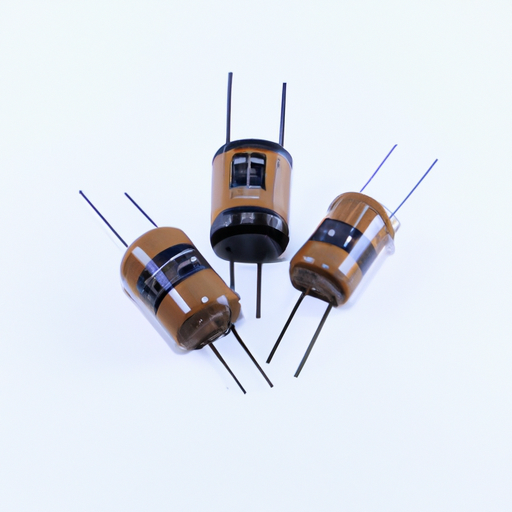

Tantalum capacitors, also known as 钽 capacitors, are widely used in electronic devices due to their high capacitance, low leakage current, and stable performance. These capacitors are made from tantalum metal, which is known for its high melting point, corrosion resistance, and excellent conductivity. In order to ensure the quality and reliability of 钽 capacitors, there are several product standards that manufacturers must adhere to.

Another important product standard for 钽 capacitors is the American National Standards Institute (ANSI) standard C390. This standard provides guidelines for the performance and testing of 钽 capacitors, including parameters such as capacitance, voltage rating, and temperature stability. Manufacturers must follow the requirements set forth in this standard to ensure that their 钽 capacitors meet the performance specifications required for various electronic applications.

In addition to these international and national standards, there are also industry-specific standards that apply to 钽 capacitors. For example, the Joint Electron Device Engineering Council (JEDEC) has established standards for 钽 capacitors used in the semiconductor industry. These standards cover aspects such as packaging, reliability, and environmental testing, and manufacturers must comply with these requirements to ensure that their 钽 capacitors meet the stringent demands of the semiconductor industry.

When it comes to the specific product standards for 钽 capacitors, there are several key parameters that manufacturers must consider. One of the most important parameters is the capacitance value, which determines the amount of charge that the capacitor can store. Manufacturers must ensure that their 钽 capacitors meet the specified capacitance value within a certain tolerance range to ensure proper performance in electronic circuits.

Another important parameter for 钽 capacitors is the voltage rating, which indicates the maximum voltage that the capacitor can withstand without breaking down. Manufacturers must ensure that their 钽 capacitors have a voltage rating that is suitable for the intended application to prevent damage to the capacitor and the electronic device in which it is used.

Temperature stability is another critical parameter for 钽 capacitors, as fluctuations in temperature can affect the performance and reliability of the capacitor. Manufacturers must ensure that their 钽 capacitors have a stable capacitance value over a wide temperature range to ensure consistent performance in various operating conditions.

In addition to these key parameters, manufacturers must also consider other factors such as leakage current, equivalent series resistance (ESR), and ripple current handling capability when designing and testing 钽 capacitors. These parameters can have a significant impact on the performance and reliability of the capacitor in electronic circuits, and manufacturers must carefully evaluate and test these factors to ensure that their 钽 capacitors meet the necessary product standards.

Overall, 钽 capacitors are essential components in electronic devices, and manufacturers must adhere to strict product standards to ensure the quality and reliability of these capacitors. By following international, national, and industry-specific standards, manufacturers can ensure that their 钽 capacitors meet the necessary performance specifications and provide reliable operation in a wide range of electronic applications.

Tantalum capacitors, also known as 钽 capacitors, are widely used in electronic devices due to their high capacitance, low leakage current, and stable performance. These capacitors are made from tantalum metal, which is known for its high melting point, corrosion resistance, and excellent conductivity. In order to ensure the quality and reliability of 钽 capacitors, there are several product standards that manufacturers must adhere to.

Another important product standard for 钽 capacitors is the American National Standards Institute (ANSI) standard C390. This standard provides guidelines for the performance and testing of 钽 capacitors, including parameters such as capacitance, voltage rating, and temperature stability. Manufacturers must follow the requirements set forth in this standard to ensure that their 钽 capacitors meet the performance specifications required for various electronic applications.

In addition to these international and national standards, there are also industry-specific standards that apply to 钽 capacitors. For example, the Joint Electron Device Engineering Council (JEDEC) has established standards for 钽 capacitors used in the semiconductor industry. These standards cover aspects such as packaging, reliability, and environmental testing, and manufacturers must comply with these requirements to ensure that their 钽 capacitors meet the stringent demands of the semiconductor industry.

When it comes to the specific product standards for 钽 capacitors, there are several key parameters that manufacturers must consider. One of the most important parameters is the capacitance value, which determines the amount of charge that the capacitor can store. Manufacturers must ensure that their 钽 capacitors meet the specified capacitance value within a certain tolerance range to ensure proper performance in electronic circuits.

Another important parameter for 钽 capacitors is the voltage rating, which indicates the maximum voltage that the capacitor can withstand without breaking down. Manufacturers must ensure that their 钽 capacitors have a voltage rating that is suitable for the intended application to prevent damage to the capacitor and the electronic device in which it is used.

Temperature stability is another critical parameter for 钽 capacitors, as fluctuations in temperature can affect the performance and reliability of the capacitor. Manufacturers must ensure that their 钽 capacitors have a stable capacitance value over a wide temperature range to ensure consistent performance in various operating conditions.

In addition to these key parameters, manufacturers must also consider other factors such as leakage current, equivalent series resistance (ESR), and ripple current handling capability when designing and testing 钽 capacitors. These parameters can have a significant impact on the performance and reliability of the capacitor in electronic circuits, and manufacturers must carefully evaluate and test these factors to ensure that their 钽 capacitors meet the necessary product standards.

Overall, 钽 capacitors are essential components in electronic devices, and manufacturers must adhere to strict product standards to ensure the quality and reliability of these capacitors. By following international, national, and industry-specific standards, manufacturers can ensure that their 钽 capacitors meet the necessary performance specifications and provide reliable operation in a wide range of electronic applications.